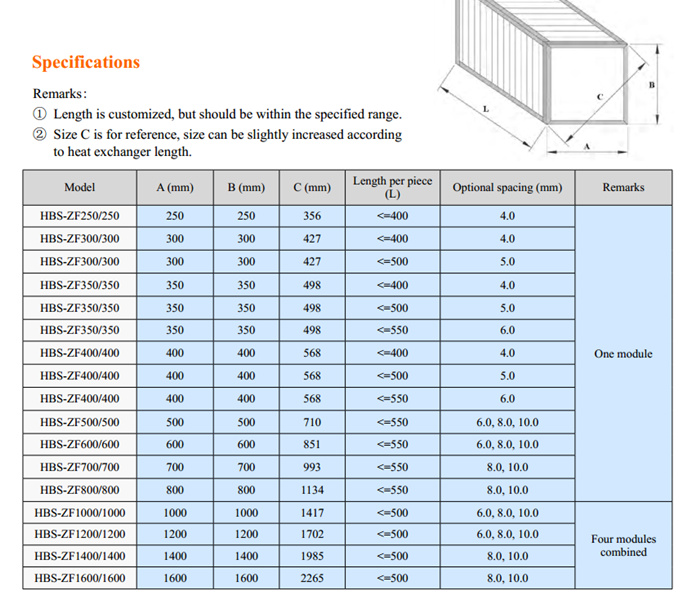

Sensible Crossflow Plate Heat Exchangers

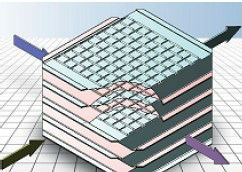

Working Principle of Sensible Crossflow Plate Heat Exchangers:

Two neighbor aluminum foils form a channel for fresh or exhaust air stream. Heat is transferred when the air streams flow crossly through the channels, and fresh air and exhaust air is totally separated.

Features:

- Sensible heat recovery

- Total separation of fresh air & exhaust air streams

- Heat recovery efficiency up to 80%

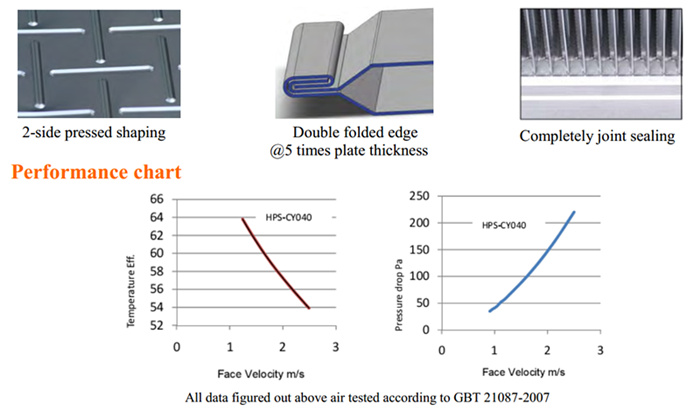

- 2-side press shaping

- Double folded edge

- Completely joint sealing.

- Resistance of pressure difference up to 2500Pa

- Under pressure of 700Pa, air leakage less than 0.6%

Material type:

B series (standard type)

Heat exchanger is made of pure aluminum foils, with galvanized end cover and aluminium alloy wrap angle. Max. air temperature 100℃, it is suitable for most of the occasion.

F series ( Anti-corrosion type)

Heat exchanger is made of pure aluminum foils cover by special anti-corrosion material, with galvanized end cover and aluminium alloy wrap angle., it is suitable for the corrosive gas occasion.

G series (high temperature type)

Heat exchanger is made of pure aluminum foils, with galvanized end cover and aluminium alloy wrap angle. Sealing material is special and allow the Max. air temperature to be 200℃, it is suitable for special high temperature occasion.

Aluminum foils thickness range from 0.12 to 0.18mm because of the different specification heat exchanger.

Application

Used in comfortable air conditioning ventilation system and technical air conditioning ventilation system. Supply air and exhaust air totally separated, heat recovery in winter and cold recovery in Summer.