Overview:

The Cosmetic Production cleanrooms allow for complete flexibility, providing each component to be individually selected and manufactured to achieve exactly the design of cleanroom required. The production of cosmetics, body and face care products requires the mandatory introduction of clean technologies. The requirements of good manufacturing practice in the perfumery and cosmetics industry are regulated by ISO 22716 Cosmetics standard, as well as GMP and other ISO normative documents.

According to these standards, the production of most cosmetic products should occur in conditions close to the manufacture of medicines, since cosmetics and perfumes come into direct contact with the human body. In case of incorrect planning of work areas, incorrect design of auxiliary rooms, inadequate installation of ventilation systems, airspace will be regularly contaminated with contaminants, chemical vapors and other particles, causing diseases, allergic reactions and skin irritation. The production of high-quality and safe perfumery or cosmetic products without the use of clean rooms and clean zones is simply impossible.

Project information:

Clean room area: 150m2;

Future expansion area: 42m2

Ceiling height: 2.2m

Design requirements:

Purification level: ISO8 & ISO9

Indoor temperature and humidity control requirements: 22±3C/42%±5%

Design and service scope:

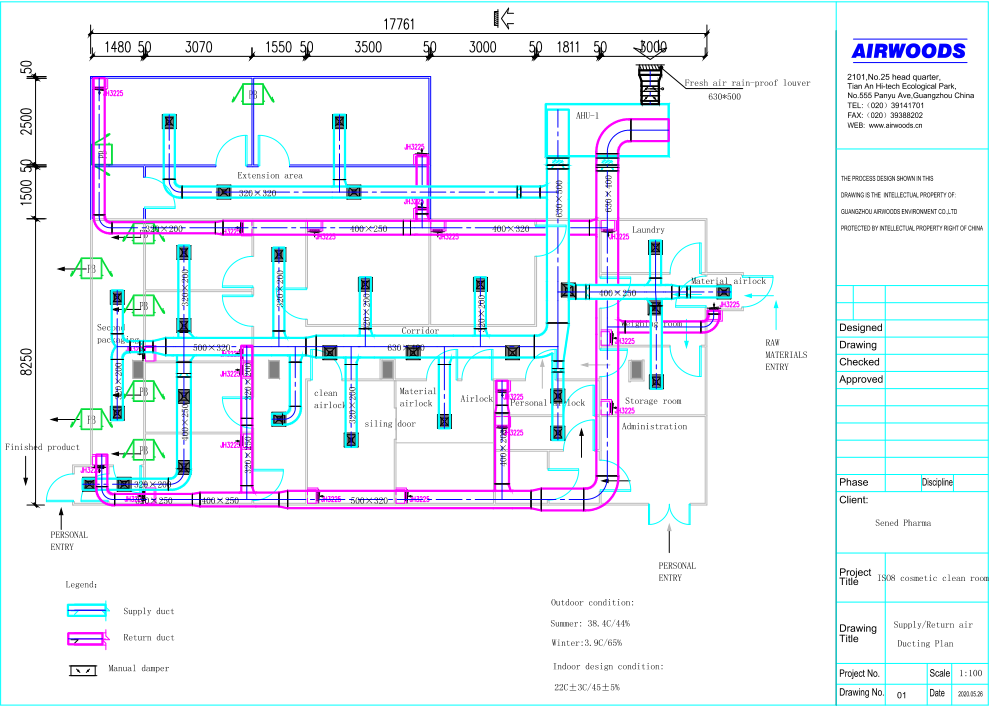

clean room decoration, lighting and purification air conditioning system.

Design idea:

Adopt integrated direct expansion purification air-conditioning system to meet the requirements of indoor constant temperature and humidity control.

Post time: Jul-15-2020