Key technical elements that affect energy efficiency

Understanding Energy recovery in rotary heat exchangers- Key technical elements that affect energy efficiency

Heat recovery systems can be divided into two categories based on the thermal parameters of the system: Systems for energy recovery and conversion from waste heat with high thermal parameters (above 70oC) and systems for energy recovery and conversion from waste heat with low thermal parameters (below 70oC).

Heat recovery and energy conversion systems above 70oC are used in technological processes that take place in the energy, food, chemical, and other process-based industries where large amounts of waste heat are released. This waste heat with high thermal parameters can be used to improve the energy and economic efficiency of enterprises by directly heating air in ventilation systems or by augmenting technological processes requiring higher temperatures (e.g. the heat source for heat pumps used for pasteurization in the food industry, or for the production of electricity in the organic Rankine Cycle or Kalina Cycle systems). Waste heat with such elevated thermal parameters can also be used for refrigeration and air-conditioning processes (e.g. converting thermal energy into chilled water using absorption or adsorption chillers).

Heat recovery and energy conversion systems below 70oC are most often used for heating purposes in residential buildings (e.g. underfloor heating with the use of heat pumps) or commercial buildings (e.g. in air handling units (AHU) for heating “fresh” or “outdoor” air by recovering heat from “used” or “exhaust” air). This article will focus on commercial building applications.

Heat recovery systems in air handling units are based on two systems that, depending on the type of solution adopted in the unit’s design, consume electricity (active systems) or not (passive systems). Active heat recovery systems in air handling units include, for example, systems based on rotary heat exchangers or reversible heat pumps. Passive heat recovery systems include cross and hexagonal heat exchangers. Characteristic for heat recovery in ventilation systems is that heat is recovered at small temperature differences between the higher temperature air stream and the lower temperature air stream, with the higher temperature air rarely exceeding 30oC (in commercial buildings, heat recovery takes place even at lower air temperatures).

Most often, heat recovery in ventilation and air-conditioning units is carried out using rotary or cross-flow (hexagonal) heat exchangers, less often using heat pumps. Rotary heat exchangers are used in AHUs where mass exchange between inlet and outlet air in the AHU is allowed (these are usually public buildings). Cross-flow and hexagonal heat exchangers are used in air handling units where mass exchange between fresh and used air cannot be allowed (e.g. hospitals). Reversible heat pumps are used when high temperature supply air is required for heating purposes.

Mass and energy balance in heat exchangers used in air handling units

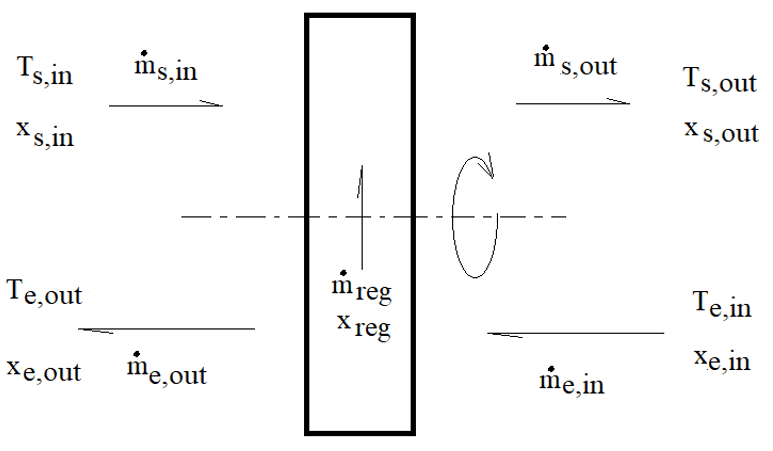

When calculating rotary heat exchanger performance for heat recovery in air handling units, in addition to energy balance, an appropriate mass balance is required. The following are energy and mass balance equations for steady-state flow conditions with the following assumption. Periodic parameter changes resulting from the exchanger’s rotational movement are averaged in the overall energy and moisture balance — that is, periodic local changes in temperature and humidity on the surface of the rotating wheel are insignificant and thus omitted in the calculations.

a) Mass, concentration, and energy balance for rotary heat exchangers:

Diagram of calculation parameters for rotary heat exchangers

Post time: Dec-03-2019