Since 2007,Airwoods dedicated to provide comprehensive hvac solutions to various industries. We also provides professional clean room solution. With in-house designers, full-time engineers and dedicated project managers, our expert team assists in every aspect of cleanroom creation—from design to construction and assembly—to provide custom-tailored solutions to a wide range of industries. Whether a customer requires a standard or highly specialized area; a positive air pressure cleanroom or negative air pressure cleanroom, we excel in working with clients’ specification, to produce solutions which exceed the expectations, not budget.

The difference between positive & negative pressure cleanroom

If you’re considering a cleanroom, you’re probably trying to gather as much information as possible. What type of cleanroom is right for you? What industry standards do you have to meet? Where will your cleanroom go? You get the picture. Well, one piece of information that might be useful to you is understanding the difference between positive and negative air pressure cleanrooms. As you probably already know, airflow plays a leading role in keeping your cleanroom to standard, but what you may not have known is that air pressure can have a big effect on that as well. So here's a broken down explanation of each positive and negative air pressure.

What is positive pressure cleanroom?

This means that the air pressure inside your cleanroom is greater than the surrounding environment. This is achieved through the use of an HVAC system, achieved by pumping clean, filtered air into the cleanroom, generally through the ceiling.

Positive pressure is used in cleanrooms where the priority is keeping any possible germs or contaminants out of the cleanroom. In the event that there was a leak, or a door opened, clean air would be forced out of the cleanroom, rather than unfiltered air being allowed into the cleanroom. This works somewhat similarly to deflating a balloon; when you untie a balloon, or pop it, air rushes out because the air pressure in the balloon is higher than the pressure of the ambient air.

Positive pressure cleanrooms are used primarily for industries where the cleanroom functions to keep the product clean and safe from particulates, like in the microelectronic industry where even the tiniest particle can damage the integrity of the microchips being manufactured.

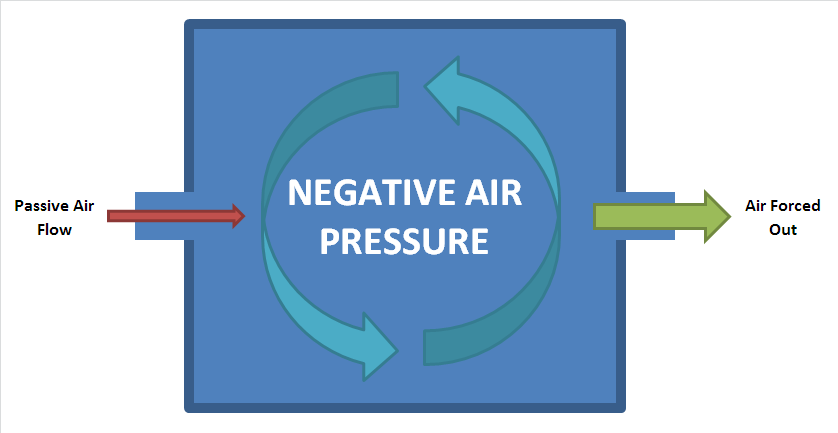

What is negative pressure cleanroom?

In contrast to a positive air pressure cleanroom, a negative air pressure cleanroom maintains an air pressure level that is lower than that of the surrounding room. This condition is achieved through the use of an HVAC system that continuously filters air out of the room, pumping clean air into the room near the floor and sucking it back out near the ceiling.

Negative air pressure is used in cleanrooms where the goal is to keep any possible contamination from escaping the cleanroom. Windows and doors have to be completely sealed, and by having a lower pressure, air outside the cleanroom is likely to flow into it, rather than out of it. Think of it like an empty cup that you set in a bucket of water. If you push the cup into the water rightside up, water flows into the cup, because it has lower pressure than the water. The negative pressure cleanroom is like the empty cup here.

The significant point of difference between the two is that positive pressure containment systems protect the process while negative protects the person .Negative air pressure cleanrooms are used in industries that manufacture pharmaceutical products, do biochemical testing, and also in hospitals to quarantine seriously contagious patients. Any air that flows out of the room has to first flow out of a filter, ensuring that no contaminants can escape.

Similarities between positive pressure and negative pressure cleanroom?

Although the functions of positive pressure and negative pressure cleanrooms are quite different, they are some similarities between the two. For example, both types require the use of:

1. Powerful HEPA filters, which, along with the other HVAC system parts, need careful maintenance

2. Self-closing doors and properly sealed windows, walls, ceilings, and floors to facilitate the maintenance of appropriate air pressure levels

3. Multiple air changes per hour to ensure proper air quality and pressure conditions

4. Ante-rooms for employees to change into the required protective clothing and deliver the necessary materials and equipment

5. In-line pressure monitoring systems

If you have any more questions regarding negative and positive air pressure cleanrooms, or if you’re looking to purchase a cleanroom for your business, contact Airwoods today! We’re your one-stop shop to getting the perfect solution. For additional information about our cleanroom capabilities or to discuss your cleanroom specifications with one of our experts, contact us or request a quote today.

Post time: Dec-22-2020