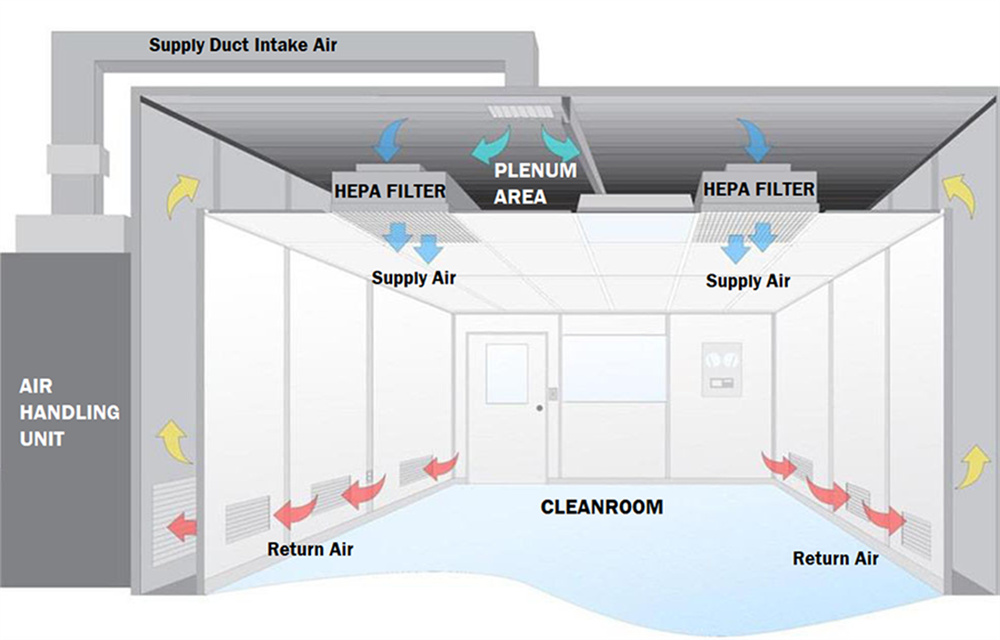

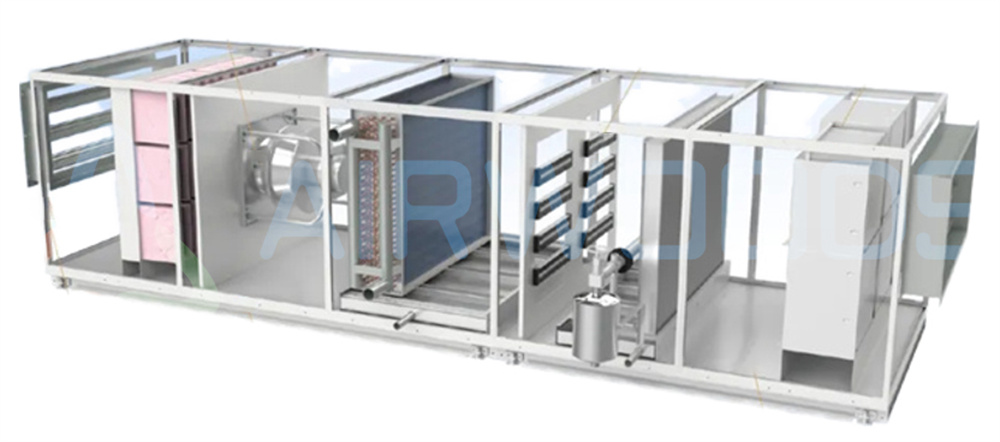

One of our esteemed clients is constructing a 300 m² pharmaceutical production plant for tablets and ointments, designed to meet ISO-14644 Class 10,000 clean room standards. To support their critical production needs, we engineered a custom hygienic air handling unit (AHU) tailored to ensure a controlled indoor environment for their clean room.

Here’s how our solution makes a difference:

✅ Optimized Air Circulation: Delivers 20–30 air changes per hour, ensuring consistent air quality and minimal contamination risks.

✅ Advanced Filtration System: Multiple filtration stages effectively remove particulates, creating ultra-clean air.

✅ Precision Climate Control: Regulates temperature and relative humidity with a smart control system, maintaining ideal conditions for sensitive pharmaceutical processes.

A controlled atmosphere—especially low indoor humidity—is critical for preserving the quality and stability of pharmaceutical products. By creating this ideal environment, the clean room and our AHU solution enable our client to achieve and maintain high production standards.

Post time: Nov-29-2024