Negative Pressure Weighing Booth

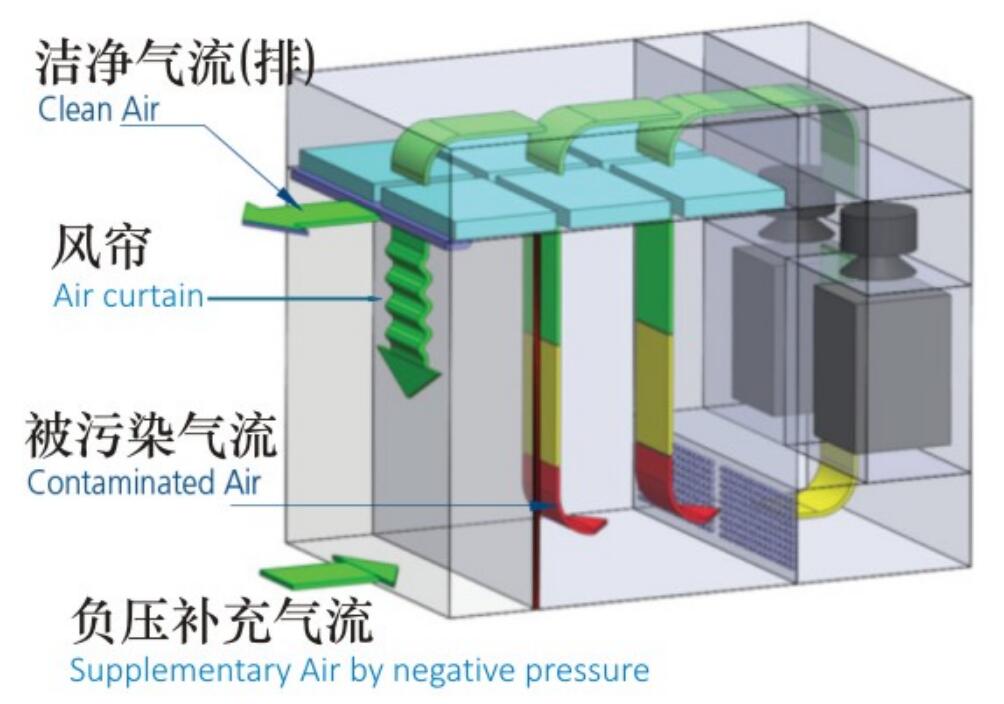

Negative pressure weighing booth is a local clean equipment, which is mainly applied in pharmaceutical proportioning weighing and sub-packing to prevent medical powder from spreading or raising, so as to avoid inhalation harm for human body and to avoid cross contamination between work-space and clean-room.

Operating principle: filtrated airborne particles from workspace air with fan, primary efficiency filter, medium efficiency filter and HEPA, negative pressure weighing booth supplies vertical unidirectional clean airflow to workspace. At the same, by venting

10~15% air volume, it achieve negative pressure between work space and clean-room, so as to prevent medical powder from spreading and raising. It can be tuned to run on constant fan frequency or air airflow speed by control system, which consists of PLC, air velocity transmitter and frequency converter.

Key technical parameter:

1. Air speed:0.3~0.6m/s adjustable

2. Illumination ≥350Lux

3. Noise <75dB

4. Efficiency: 99.999%@0.5um

5. Control: Auto& Manual/Manual

6. Standard dimension: Workspace: aW* bH* cD

Outer size:(a+100)W*(b+500)H*(c+600)D

|

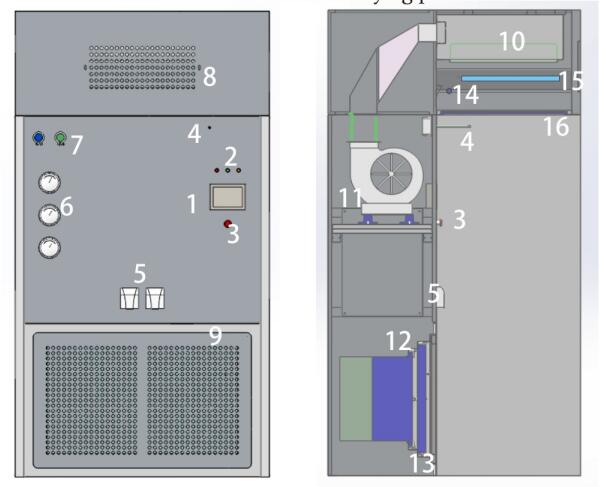

1.Touchscreen 2.Indicators 3.Emergency stop 4.Air speed transmitter 5.Dust-proof power socket 6.Differential pressure gauge 7.PAO testing ports 8.Adjustable air outlet 9.Perforated plate 10.Gel seal HEPA 11.Fan 12.Medium efficiency filters 13.Primary efficiency filters 14.UV Germicidal lamp 15.LED light 16.Flow equalizing membrane |