Heat Pipe Heat Exchangers

Main Feature of Heat Pipe Heat Exchangers

1. Applying cooper tube with hydrophilic aluminum fin, low air resistance, less condensing water, better anti-corrosion.

2. Galvanized steel frame, good resistance to corrosion and higher durability.

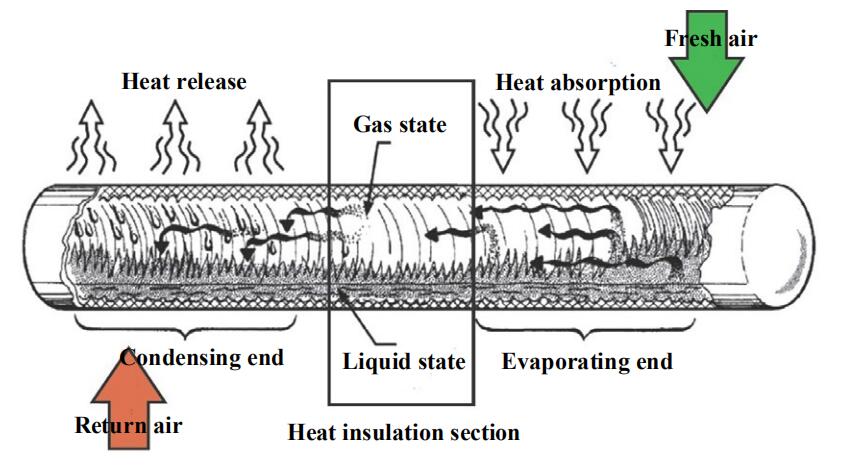

3. Heat insulation section separates heat source and cold source, then liquid inside the pipe has no heat transfer to outside.

4. Special inner mixed air structure, more uniform airflow distribution, making heat exchange more sufficient.

5. Different working area designed more reasonably, Special heat insulation section avoids leakage and cross contamination of supply and exhaust air, heat recovery efficiency is 5% higher than the traditional design.

6. Inside the heat pipe is special fluoride without corrosion, it is much safer.

7. Zero energy consumption, free of maintenance.

8. Reliable, washable and long life.

Working principle

Take summer as sample:

Application

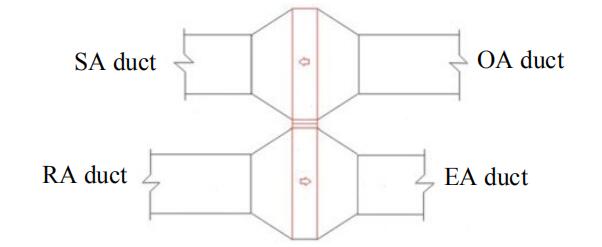

Application 1: duct installation

Connect the air ducts to the heat pipe heat exchanger directly, installation is easy, investment saved and energy recovery.

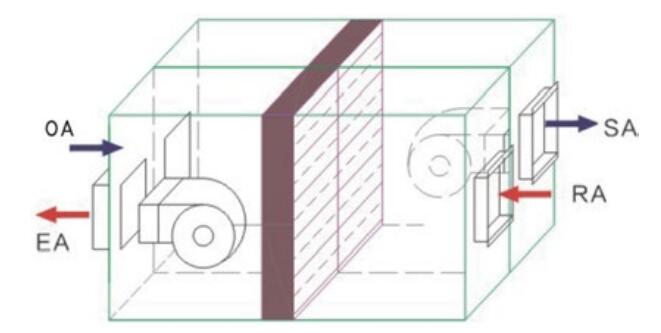

Application 2: Heat recovery ventilator

Heat pipe heat exchanger can be installed inside heat recovery ventilator horizontally, with the supply fan and exhaust fan to achieve energy recovery.

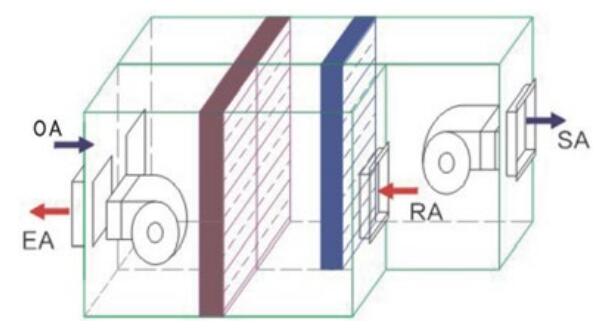

Application 3: Air handling unit

Heat pipe heat exchangers are widely used in air handing units, it have functions of energy recovery, free dehumidification and re-heating, etc.

Application range

- Residential ventilation system, HVAC energy recovery system.

- Waste heat/cool recovery place.

- Clean room.