factory Outlets for Class 100 Cleanroom Design - Vertical Flow Clean Bench – Airwoods

factory Outlets for Class 100 Cleanroom Design - Vertical Flow Clean Bench – Airwoods Detail:

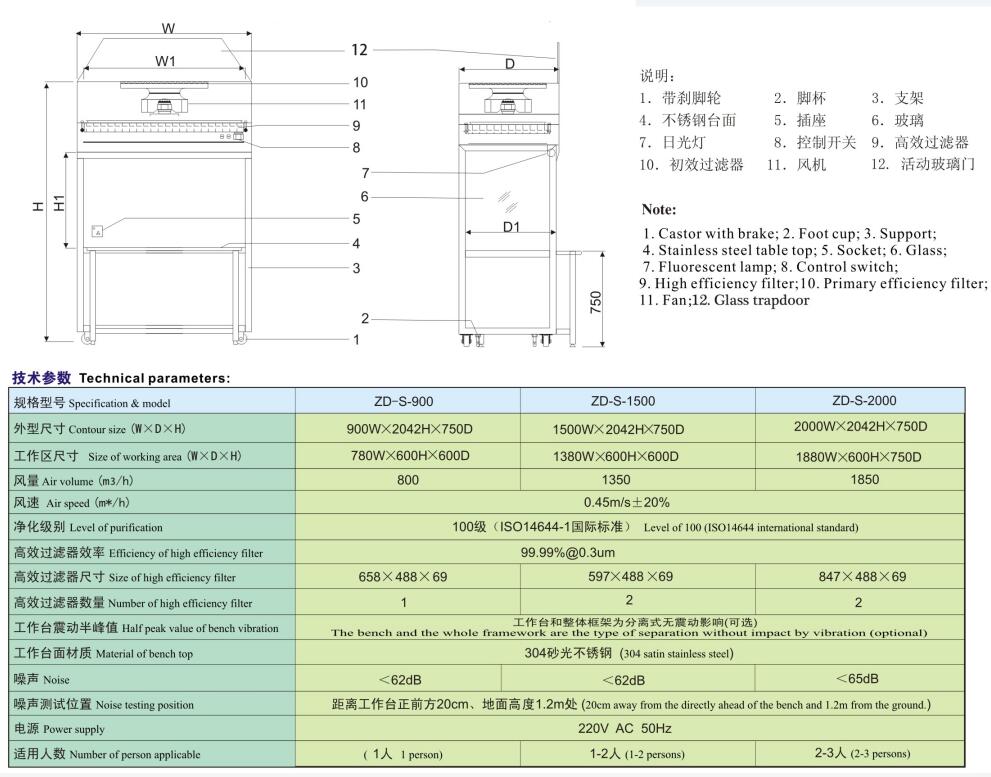

The vertical air clean bench adopts the form of air flow in the purification principle of vertical one-way flow, which integrates the low-noise centrifugal fan, static pressure case and high efficiency filter into a single unit structure. This product can adopt the separating bench to reduce the impact by vibration.It is a kind of air purification equipment providing a stronger versatility for local high-clean environment.The use of this product can improve the process conditions,enhance the quality of product,and increase the rate of finished products.

Features:

·The degree of cleanness CLASS 10 conforms to the international standard ISO1466-1.

·The low-noise fan system with adjustable air volume is adopted to guarantee that the air speed in the working area is always in an ideal condition.

·The case body is made of the steel plate with electrostatic coating and the operating.

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for factory Outlets for Class 100 Cleanroom Design - Vertical Flow Clean Bench – Airwoods , The product will supply to all over the world, such as: Malaysia, Nepal, Barcelona, During the development, our company has built a well-known brand. It is well highly acclaimed by our customers. OEM and ODM are accepted. We are looking forward to customers from all over the world to join us to a wild cooperation.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!