Desiccant Wheels

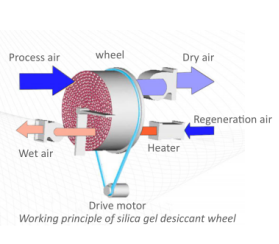

How the desiccant wheel works?

| The easy dry desiccant wheel works on the principle of sorption, which is the adsorption or the absorption process by which a desiccant removes water vapor directly from the air. The air to be dried passes through the desiccant wheel and the desiccant removes the water vapor directly from the air and holds it while rotating. As the moisture-laden desiccant passed through the regeneration sector, the water vapor is transferred to a heated air stream, which is exhausted to the outside. This process is continuous, allowing for highly effective and uninterrupted dehumidification. |

|

High efficiency and reliability

- High moisture removal capacity

Silica gel desiccant wheel is made of high active silica gel, cover rate over 82%, active silica is formed inside the fiber, because of the large number of pores on the fiber surface, the density is small, this means the major parts of the desiccant wheel are made of silica gel, so, silica gel desiccant wheel has high efficient performance in dehumidification operation. Density of the wheel in dry state is 240kg/m3, and the hygroscopic capacity in the humid environment can reach 40% higher than in dry state.

- High strength

According to the test, surface compressive strength of silica gel desiccant wheel is more that 200kPa (0.2Mpa).

- Water washable

Silica gel desiccant wheel can be washable by clean water or non- alkaline liquid.

- Non-flammable

Silica gel desiccant wheel has good fireproof performance because of its special material, according to the American Institution ASTME test, it is E-84 standard compliant, fire burning index and smoke index are Zero.

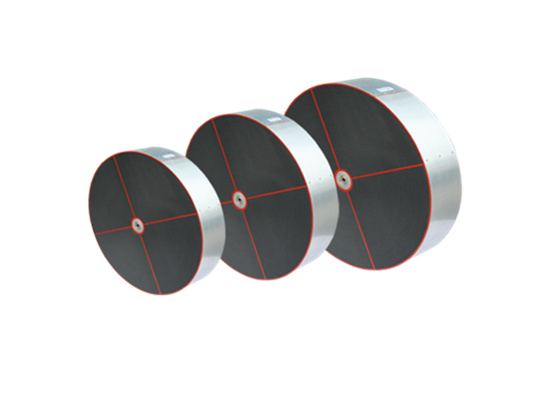

- Customer made size

According to different project requirement, desiccant wheel size is customizable.

- Flexible construction

Wheel Structure configuration is also customizable, for example the metal material selection for construction, and the flange installation, etc. For large wheels, they can be segmented for transportation and site assembly.

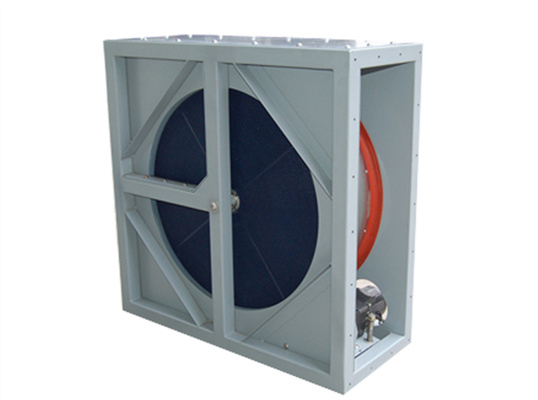

Features of desiccant dehumidifying cassettes:

- High strength welding frame

- Laser cutting with high precision

- High temperature powder coated finish with long service life

- Special sealing strips design minimizes air leakage, durable and small friction.

- Imported motor and belt, safe and reliable, chain driving without slip

- Rotor depth 100, 200 and 400mm available

- Suitable for continuous operation

- Quick and easy to service

- Easy access to all major components

- Quick serviceability and maintenance free operation.