18 Years Factory Scroll Chiller System - CVE Series Permanent Magnet Synchronous Inverter Centrifugal Chiller – Airwoods

18 Years Factory Scroll Chiller System - CVE Series Permanent Magnet Synchronous Inverter Centrifugal Chiller – Airwoods Detail:

| High-speed motor direct-driven two-stage impellerUnit adopts high-speed motor direct-driven two-stage impeller. Speed-up gears and 2 radial bearings are canceled, which will improve efficiency and reduce mechanical loss by at least 70%. With direct drive and simple structure, compressor works reliably in smaller size. Volume and weight of the compressor is only 40% of the same capacity conventional compressor. Without the high-frequency noise of speed-up gears, compressor’s operating sound is much lower. That is 8dBA lower than a conventional unit. |  |

|

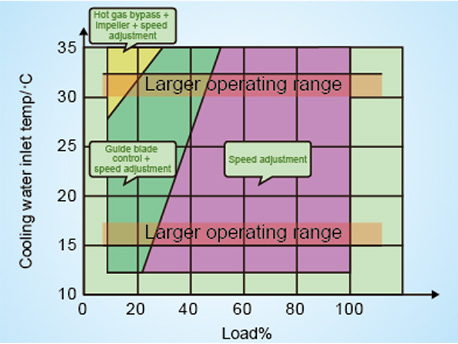

All-condition “wideband” pneumatic design

Impeller and diffuser are optimized to realize high-efficiency operation of compressor under 25-100% load. Compared with conventional design that is based on full load operation, this design can reduce compressor’s efficiency attenuation. Conventional inverter centrifugal chiller realizes capacity control by the variable speed of compressor and the variable opening angle of guide vane which begins to turn down under 50~60% load. However, Gree CVE series centrifugal chiller can directly change the speed of compressor under 25~100% load to reduce throttling loss of guide vane and improve working performance under all conditions. |

|

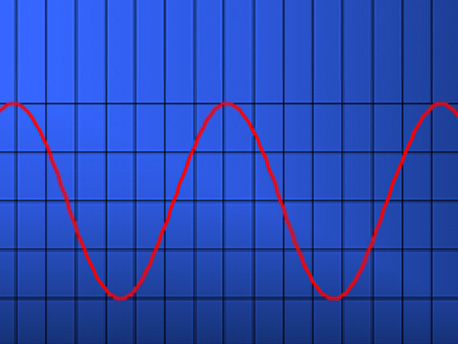

Installed sine-wave inverter

By adopting position-sensorless control technology, motor’s rotor can be positioned without probe. With PWM controllable rectifying technology, inverter can output smooth sine wave to improve motor efficiency. Inverter is directly installed on the unit, saving floor space for customers. In addition, all communication wires are connected in factory to improve unit’s reliability. |

|

|

Low viscosity vane diffuser

Unique low viscosity vane diffuser design and airfoil guide vane can turn high-speed gas into high static pressure gas effectively to realize pressure recovery. Under partial load, vane diversion reduces backflow loss, improves partial load performance, and expands unit’s operating range |

|

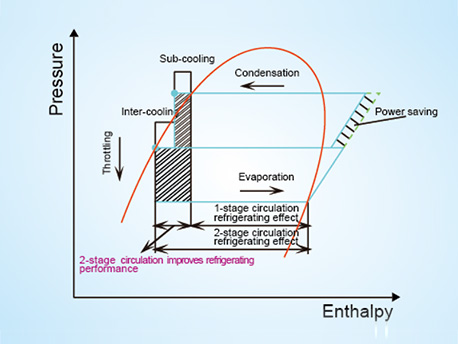

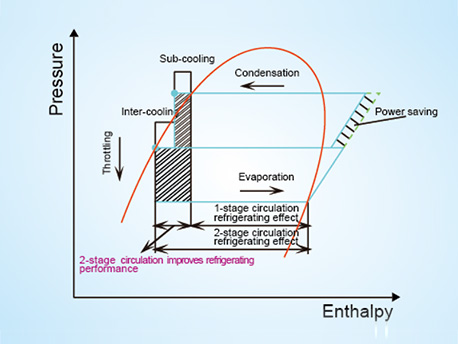

Two-stage compression technology

Compared with single-stage refrigeration system, two-stage compression improves the circulation efficiency by 5%~6%. Compressor rotational speed is lowered so that compressor is more reliable and durable.

|

|

|

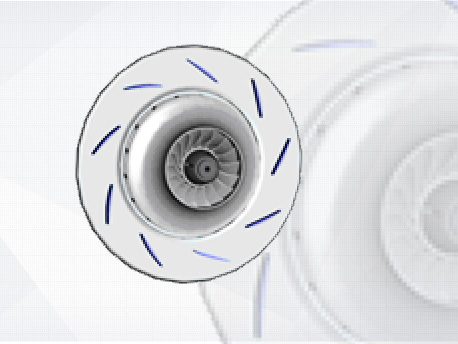

High-efficiency hermetic impeller

Compressor impeller is a ternary hermetic impeller, which is more efficient and reliable than an unshrouded impeller. It adopts airfoil 3-dimensional structure so that it is more adaptive. Through finite element analysis, 3-coordinate inspecting machine, dynamic balance test, over-speed test and actual test under actual working condition, it is made sure that impeller meets design requirement and is capable of stable operation. Impeller and basic shaft adopt keyless connection, which can avoid partial stress concentration and rotor’s additive off-balance that is caused by key connection, thus improving compressor’s operation stability.

|

|

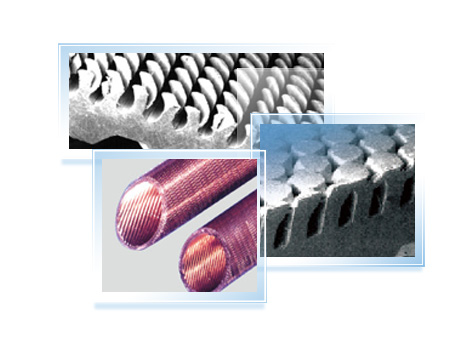

High-efficiency heat exchanger

Heat exchange surface is designed based on heat-transfer mechanism. It is optimized to reduce flowing pressure loss and energy consumption. Sub-cooler is equipped at the bottom of condenser. With multiple flow restraints, sub-cooling degree can be up to 5℃. Middle isolating board adopts light pipe that is twice as thick as threaded pipe to be joined with supporting board, therefore, copper pipe won’t be damaged under the impact of high-speed refrigerant. 3-V grooved tube plate design is adopted to guarantee sealing effect.

|

|

|

Advanced control platform

High-performance 32-bit CPU and DSP digital signal processor is used. The high data collection accuracy and data processing capacity ensure the real-time feature and accuracy of system control. Together with the colorful LCD touch screen, user can easily realize auto control and manual control in debugging. It also adopts intelligent Fuzzy-PID compound control algorithm, which is integrated with intelligent technology, fuzziness technology and normal PID control algorithm, so that system is capable of quick response speed and stable performance.

|

Product detail pictures:

Related Product Guide:

Our target should be to consolidate and improve the high-quality and repair of current goods, in the meantime regularly produce new solutions to meet unique customers' needs for 18 Years Factory Scroll Chiller System - CVE Series Permanent Magnet Synchronous Inverter Centrifugal Chiller – Airwoods , The product will supply to all over the world, such as: Sweden, Czech Republic, Holland, Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.